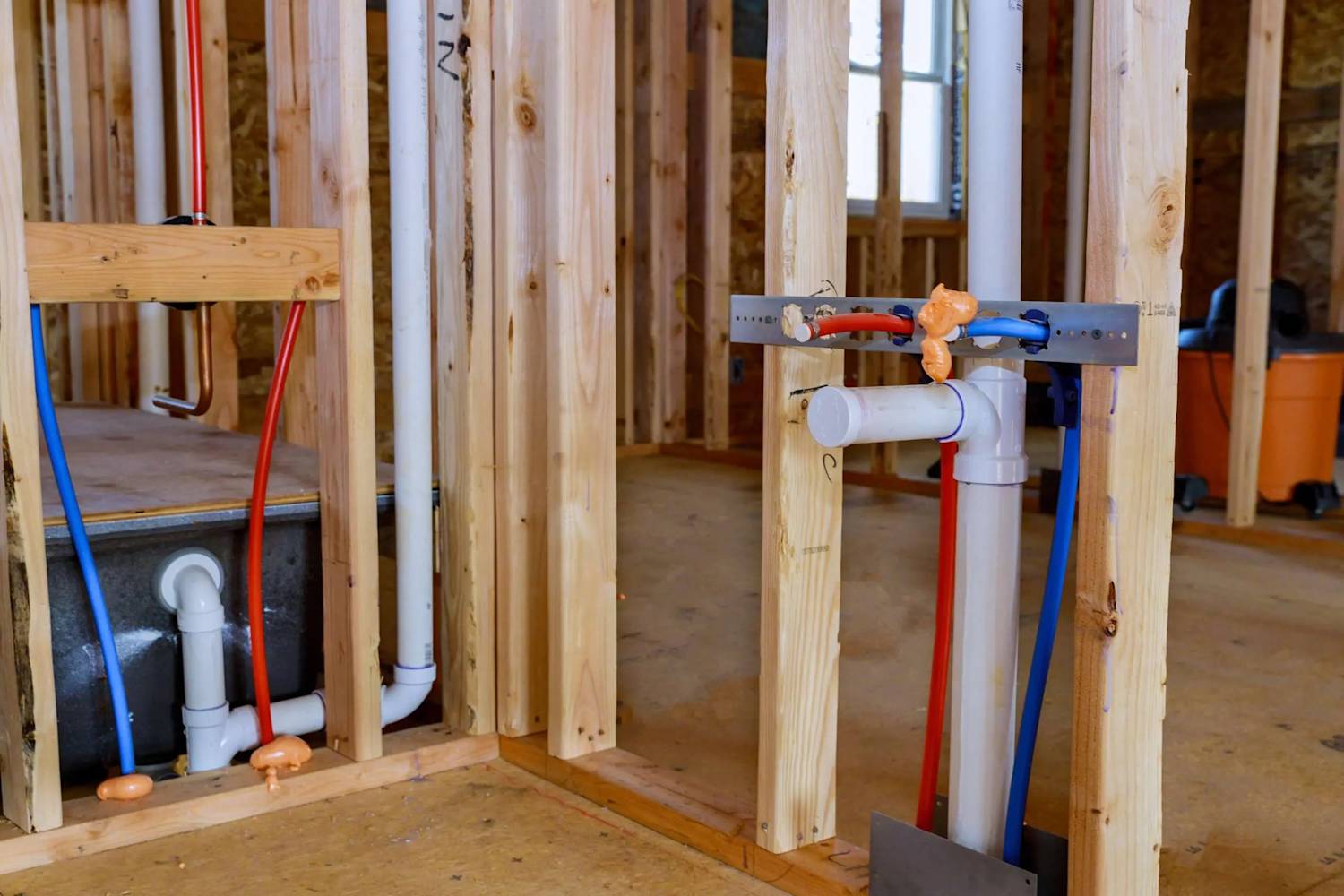

Rough-in plumbing refers to the process of installing the primary pipes and components of a plumbing system before final fittings are added. This stage occurs before the walls are sealed, allowing easy access for the installer. Rough-in plumbing typically includes the installation of water pipes, drain pipes, waste pipes, vents, and shut-off valves.

These pipes and components form the foundation of the plumbing system, providing the necessary framework to install fixtures like sinks, toilets, and showers.

Step 1: Rough-In Plumbing (Usually the First Step)

This phase is typically carried out by a professional plumber or plumbing contractor, who assesses the area and determines the ideal spots for the pipes and other components. This may involve designing a layout for the area, taking measurements, and deciding on the appropriate pipe sizes and materials.

It’s important to keep in mind the rough-in plumbing cost, which varies based on the size of the project and the materials used. While rough-in plumbing is an essential and foundational step, understanding the cost can help you budget effectively for the entire plumbing installation process.

Once the rough-in plumbing is completed, the plumber usually installs the fixtures (like sinks and toilets) and connects the pipes to them. The plumber ensures that the pipes are properly connected, secured, and functioning correctly before sealing the walls. Any additional plumbing work, such as adding a shower, will be completed once the walls are closed.

Rough-in plumbing is a critical step in the installation of a new plumbing system as it provides the structure for fixture installation and ensures the system operates effectively. By considering the rough-in plumbing cost early on, homeowners can avoid any surprises and plan accordingly for the final stages of plumbing installation.

What to Consider When Planning a Rough-in Plumbing Layout

Several important factors need to be considered when planning a rough-in plumbing layout:

- Pipe Size and Type: Choosing the correct pipe material and size is crucial because it directly affects the pressure the pipes can handle.

- Fixture Placement: The location of fixtures like sinks, toilets, and showers should be carefully planned, along with the pipe sizes needed to connect them.

- Shut-off Valves: Ensure that shut-off valves are placed in easily accessible locations for emergency situations.

- Vents: Vent placement is also important for expelling air and gases from the plumbing system. Vents should be positioned away from openable windows and as high as possible for easy access.

These considerations are vital to ensure the plumbing system is installed properly and functions efficiently. Trying to install the plumbing system yourself without expertise may not be the best idea.

What Kind of Pipes and Parts Are Typically Used in Rough-In Plumbing?

When installing a rough-in plumbing system, various types of pipes and components may be used. Copper, PVC, and PEX are the most common pipe materials. Copper is the traditional, highly durable option, while PVC and PEX are more affordable alternatives.

The components involved in rough-in plumbing include shut-off valves, supply lines, waste lines, vent pipes, and drain traps. Shut-off valves control the water supply to specific fixtures, while supply lines deliver water to them. Waste lines remove wastewater from fixtures, and vent pipes expel air and gases from the plumbing system. Drain traps are designed to prevent sewer gases from entering the home.

Additionally, fittings like elbows and couplings are used to securely connect pipes and components, ensuring the plumbing system functions properly. Installing these various pipes and components correctly is essential for creating a safe and efficient plumbing system.

How Can a Plumbing System Be Made to Last?

To ensure a plumbing system lasts, regular maintenance is necessary. This includes flushing pipes to remove buildup, checking for leaks, and ensuring all components are in good working condition. Plumbers should also inspect for corrosion or damage, as these could lead to more significant issues down the line.

Using high-quality materials when installing the system is essential for its durability. Properly installing fixtures and choosing the right pipe materials suited for the application further contributes to the longevity of the plumbing system. Taking these preventive steps helps maintain the plumbing system for many years.

What Safety Precautions Should Be Considered when Installing a New Plumbing System?

When installing a new plumbing system, safety is paramount. This involves wearing appropriate protective clothing, using the correct tools and materials for the job, and strictly adhering to local building codes and regulations. It’s also essential to secure all fixtures properly to avoid accidents or injuries.

Following installation instructions carefully is key to preventing mistakes that could lead to water damage or leaks. Moreover, keeping the work area tidy and organized helps avoid potential hazards. By taking these safety measures into account, you can ensure a smooth and secure plumbing installation.

What Factors Should Be Considered when Selecting the Type and Size of Pipes and Components?

Selecting the right type and size of pipes and components for a plumbing system requires careful consideration. The first factor is to ensure that the materials comply with local building codes, as regulations may dictate what materials can be used. Additionally, the pipes must match the required capacity for the fixtures they will supply.

Size is another important factor, as larger components may be needed to ensure sufficient water flow for certain fixtures. Environmental factors, such as the climate or soil composition, should also be considered, as these could affect the pipes’ longevity and susceptibility to corrosion. Taking all of these considerations into account ensures a functional and safe plumbing system.

What Are the Most Common Mistakes when Installing a New Plumbing System?

Common mistakes in plumbing installation include using inappropriate materials, failing to properly seal connections, neglecting to follow local codes and regulations, and not providing enough drainage space. Additionally, improperly installing fixtures like toilets or sinks can lead to leaks or water damage.

Since plumbing installation can involve potentially dangerous work, safety precautions are critical. Using protective gear and maintaining a clean workspace can minimize the risk of accidents. Proper planning and attention to detail are essential for ensuring that a new plumbing system is installed correctly.

What to Do to Keep a Plumbing System Working Correctly Once the Walls Are Closed In?

A plumbing system should be tested before and after framing to ensure it functions properly once the walls are closed. This involves running water through each fixture and checking connections for leaks. Exposed pipes should be insulated with foam to keep them warm.

Over time, the system should be inspected for any signs of wear or damage to prevent further issues. These steps help ensure the plumbing system works even with walls in place.

Additional Services Required After Installation:

In addition to the initial plumbing installation, regular maintenance and inspections are crucial to keep everything running smoothly. Over time, repairs or upgrades may be needed if damage occurs. It’s also important to watch for any water leaks that could cause damage in surrounding areas. Taking these measures will ensure the plumbing system continues to perform optimally for years.

Conclusion

Rough-in plumbing generally receives positive feedback, especially regarding the time and money saved during installation. It’s a relatively straightforward task for those with moderate plumbing experience.

Many also appreciate the neatness of the finished work and the longevity of the plumbing when done properly. Additionally, many report higher satisfaction with rough-in plumbing compared to other installation methods.